U.S. Soy Goes Into 100 Million Panels of Purebond Plywood

• Good news for home owners, workers and U.S. soybean farmers •

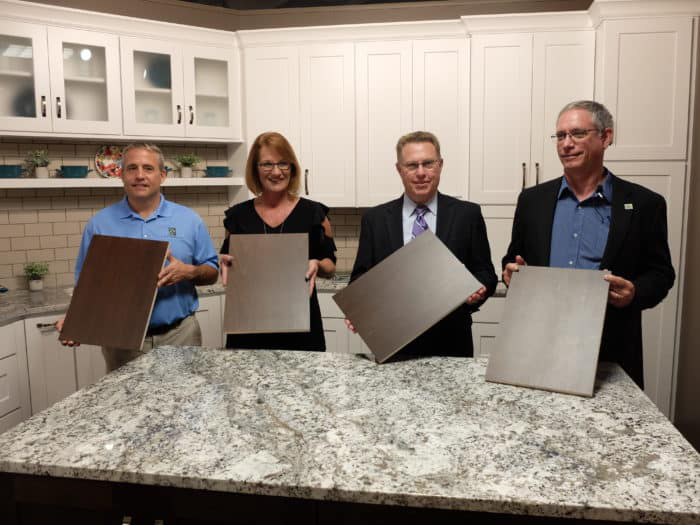

June 27, 2019 – A nature-inspired solution has achieved a major milestone. U.S. soybean farmers gathered alongside Salina cabinetry workers at Crestwood Inc. to celebrate the use of U.S. soy inside 100 million panels of Columbia Forest Products’ (CFP’s) Purebond® plywood.

The innovation has benefited thousands of customers, woodworking employees and U.S. farmers. Through the soybean checkoff, the United Soybean Board (USB) has supported soy research on the technology and partnered with CFP to educate architects and other customers about its value.

•

“U.S. soybean farmers appreciate the demand for soy that Columbia Forest Products and its customers have created for our crop that is grown by about 515,000 farms across the nation,” said USB director Lance Rezac, who grows soybeans near Onaga. “We are also proud that U.S. soy’s sustainability has contributed to the well-being of manufacturing workers, families in their homes, employees at offices and even movie sets where this product is used to avoid exposure to added formaldehyde.”

The PureBond story starts with the science of biomimicry, which studies nature then imitates its designs. Oregon State University researcher Kaichang Li looked to the Pacific Ocean for insight on how to develop a practical, scalable and cost-effective way to convert totally away from formaldehyde-based resin systems in the hardwood plywood industry.

Inspiration came from observing that mussels secret proteins to defy pounding waves. The research path led to protein-rich soy flour, which is the essential ingredient to make plywood without any added formaldehyde from standard veneer-core and composite hardwood plywood core panels. The soy-flour product delivered adhesion and water resistance.

The U.S. Environmental Protection Agency (EPA) honored the researchers who developed the soy-based panel assembly approach with the 2007 Presidential Green Chemistry Award. According to EPA, the technology represented the “first cost-competitive, environmentally friendly adhesive that replaced the toxic urea-formaldehyde (UF) resin.”

The North Carolina-headquartered company first offered the product to customers in 2005. Importantly, PureBond provides performance benefits yet is cost-competitive with traditional panels made using UF construction.

“Columbia’s environmental commitment remains strong. Our market position is about being honest and transparent with the materials we use,” said Todd Vogelsinger, CFP’s director of marketing. “Our customers want to know what they’re buying, how it was made, and what it was made with, so we are proud to say we shrank our environmental footprint with U.S. soy.

“The soy benefit means that, in addition to appreciating the visual and performance qualities of their furniture for decades into the future, our customers can also appreciate the special qualities of the material. The story of what you can’t see is as exciting as the story that the furniture tells on its own.”

CFP’s plywood products are available through a network of wholesale distributors, select Home Depot stores, and fabricators like Crestwood that make custom cabinetry, furniture and even caskets. Crestwood’s 300,000-square-foot manufacturing plant in Salina is one of the nation’s most modern woodworking facilities. The multi-generation family business was an early adopter of CFP’s decorative plywood that offers environmental benefits thanks to being made with CFP’s U.S. soy flour-based resin system.

“We are always looking for ways to better our products to meet customer needs,” said Mike Junk, Crestwood’s president. “PureBond is a cost-neutral product that also gives air-quality benefits to our customers, as well as employees. We are excited that each piece of furniture we make also uses soybeans like the ones grown here in our state.”

Because of their potential to create new markets for soybeans, U.S. soybean farmers have invested millions of dollars to research, test and promote biobased products. Much of that work was done through USB – 73 U.S. soybean farmers appointed by the U.S. secretary of agriculture to invest soybean-checkoff funds. As stipulated in the Soybean Promotion, Research and Consumer Information Act, the federal Agriculture Department’s Agricultural Marketing Service has oversight responsibilities for the soybean checkoff.

The Kansas Soybean Commission, established in 1977 and headquartered in Topeka, includes nine volunteer farmer-commissioners who are elected by their peers. They oversee investments of the legislated “soybean checkoff” assessment in research, consumer information, market development, industry relations and farmer outreach to improve the profit opportunities for all Kansas soybean farmers.

For more information, contact Communications Director Brad Parker.

Facebook: www.facebook.com/KansasSoybean

Twitter: www.twitter.com/KsSoybean

Instagram: www.instagram.com/KsSoybean

Pinterest: www.pinterest/KansasSoybean

YouTube: www.youtube.com/KansasSoybean

Flickr: www.flickr.com/kansas-soybean

SoundCloud: www.soundcloud.com/KansasSoybean

Mobile app: www.KsSoy.org/app